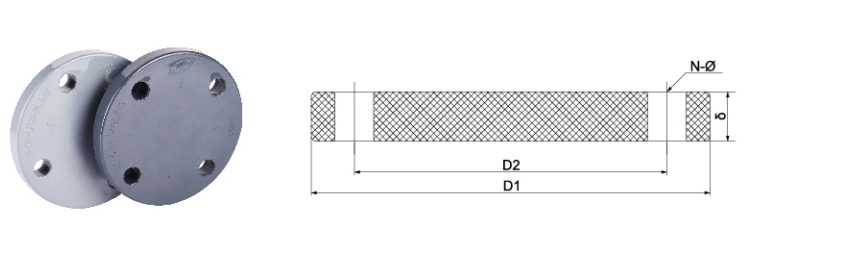

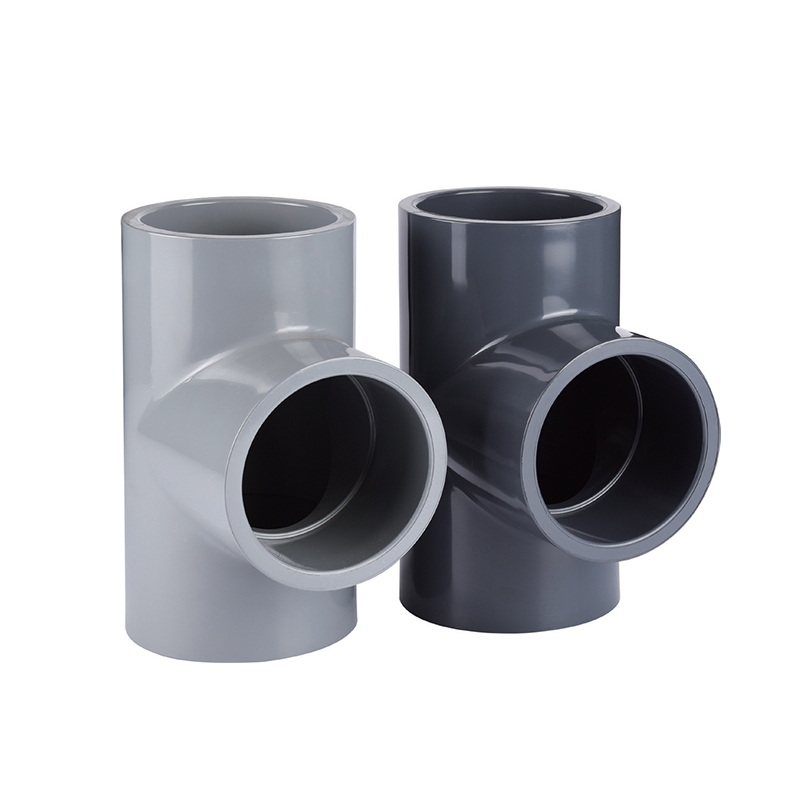

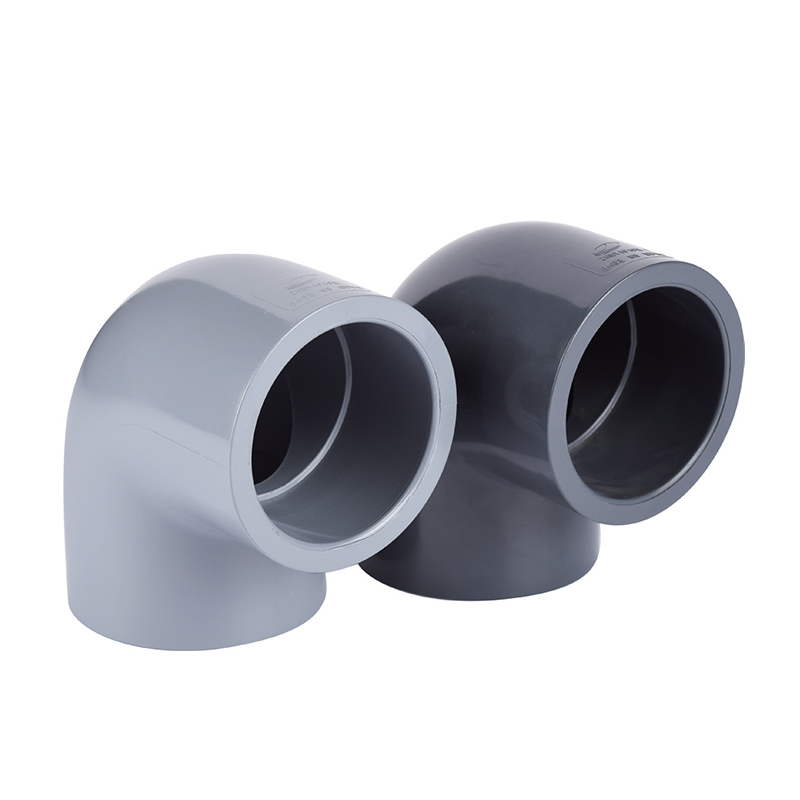

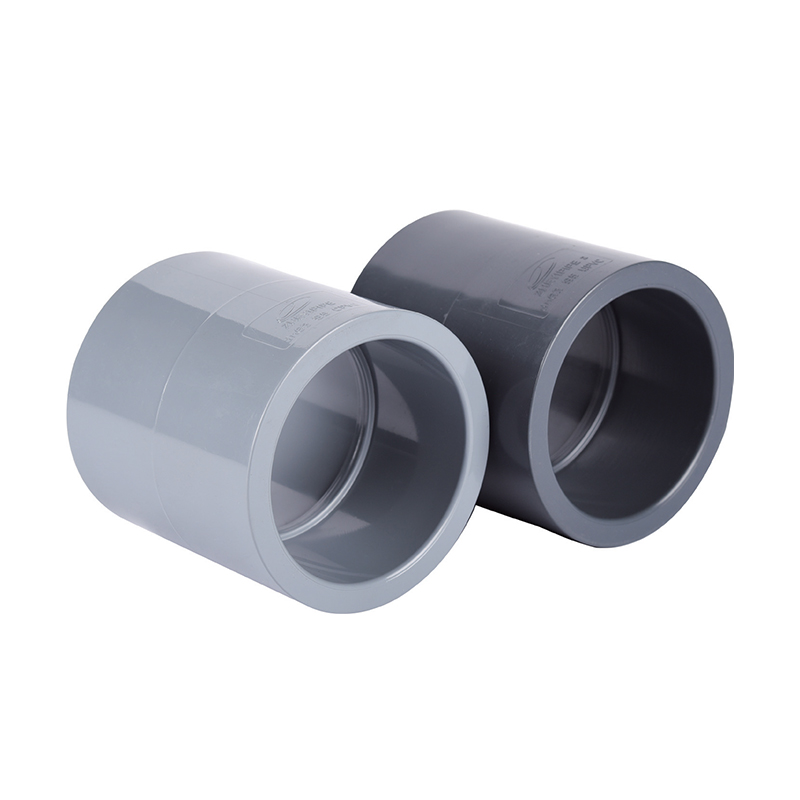

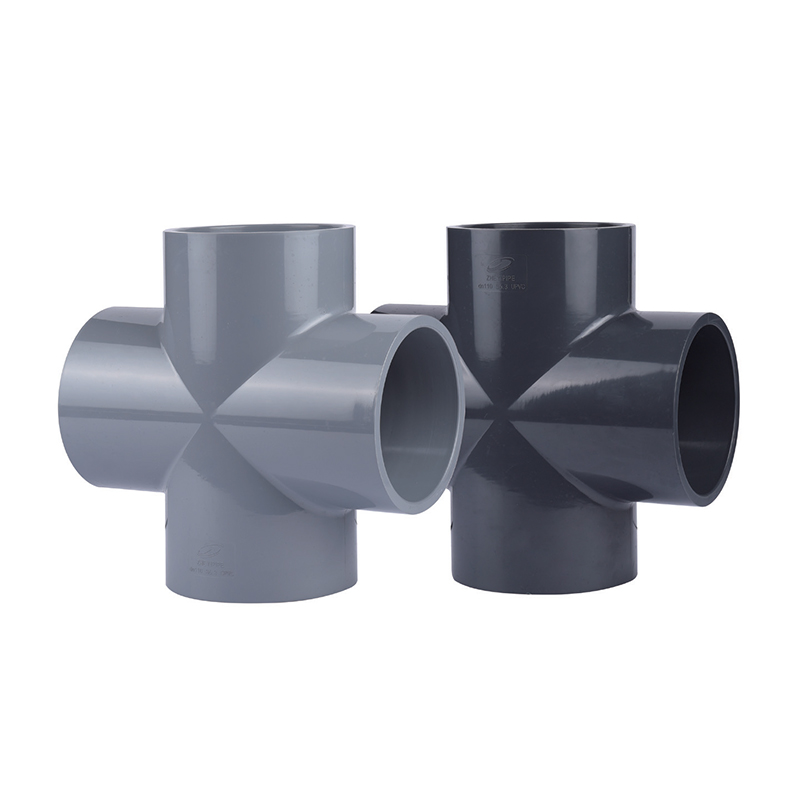

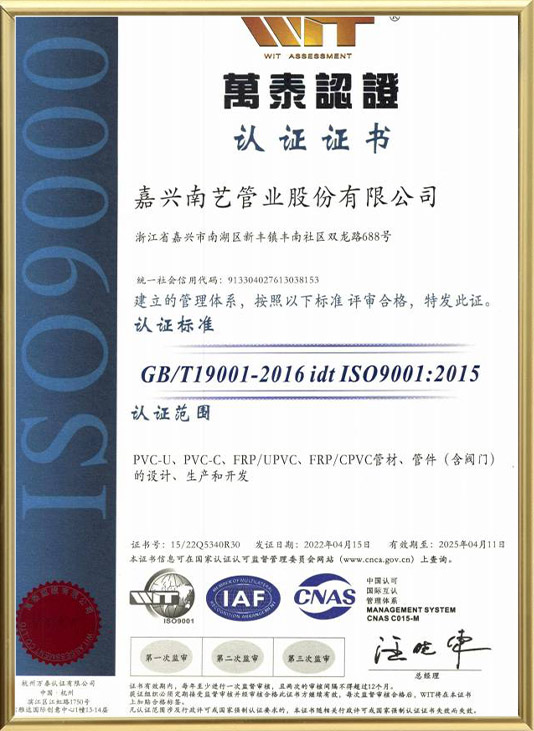

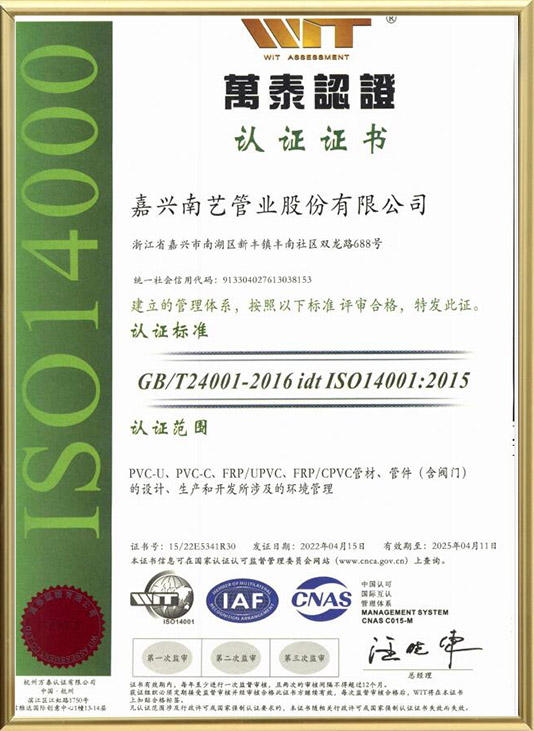

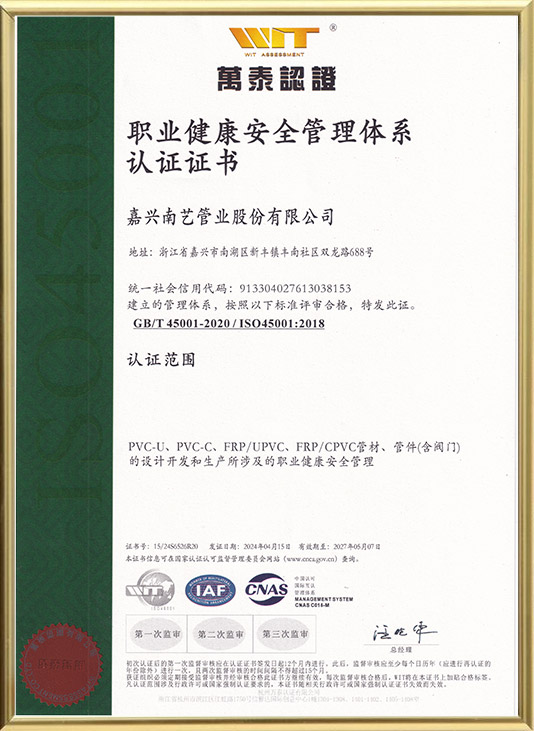

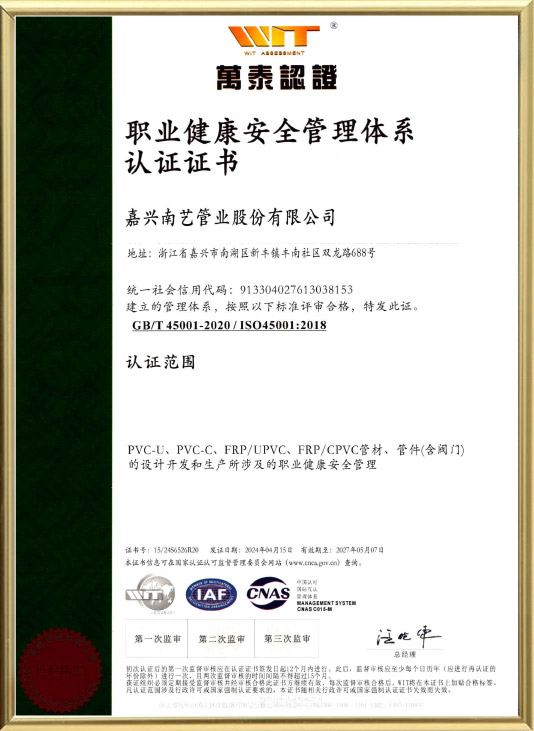

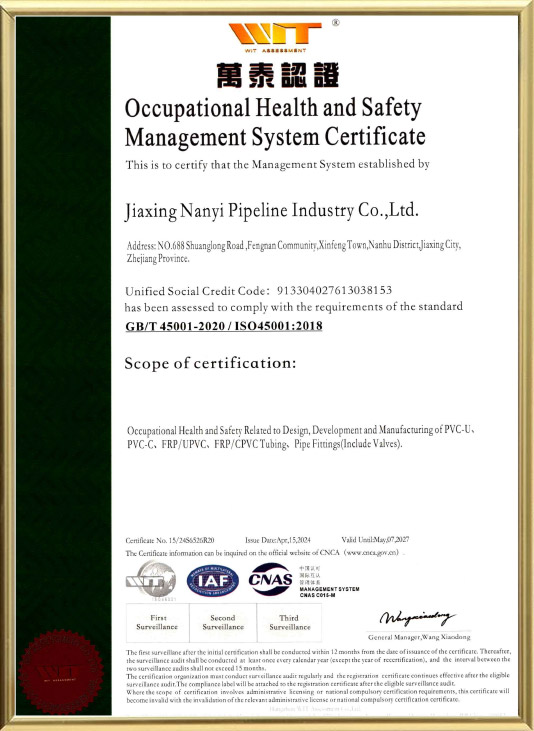

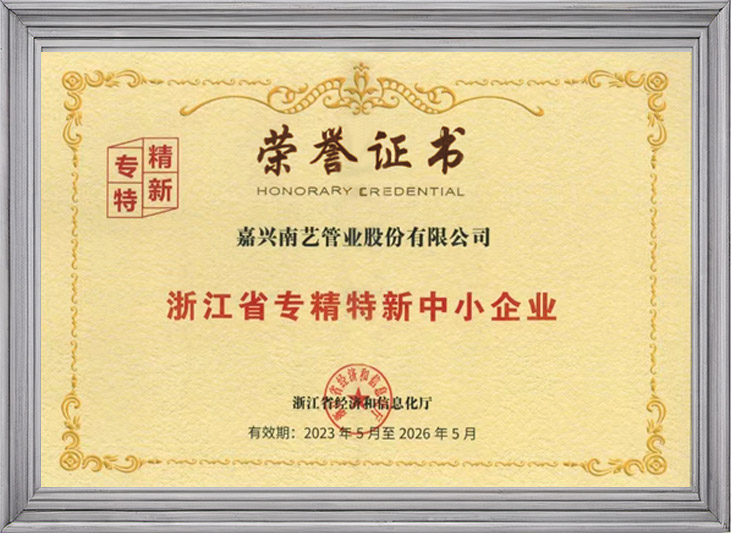

ZHEYI Group Evet Çin SCH8O/DIN UPVC/CPVC Blind Flange Gıda endüstrisi/otomotiv/elektronik için tedarikçi Ve özel yapılmış SCH8O/DIN UPVC/CPVC Blind Flange Gıda endüstrisi/otomotiv/elektronik için fabrika. 2007 yılında kurulduk ve CPVC ve UPVC endüstriyel borularının araştırma ve geliştirme, üretim, satış ve servisine odaklandık. Şirket, özel ekipman üretim lisansı, Zhejiang Eyaleti suyla ilgili ürün hijyen lisansı, IS09001 kalite yönetim sistemi sertifikası, IS014001 çevre yönetim sistemi sertifikası ve IS045001 iş sağlığı ve güvenliği yönetim sistemi sertifikası dahil olmak üzere bir dizi sertifika elde etti. Şirketin 50 den fazla bağımsız fikri mülkiyet hakkı ve kendi kendine işletilen ithalat ve ihracat hakları vardır. Şirket, çeşitlendirilmiş ürünler ve daha iyi hizmetler sunmak için Almanya ve Amerika Birleşik Devletleri nden ileri teknoloji, takım ekipmanı ve benzersiz hammaddeler ve yönetim sistemleri tanıttı. Yıllar içinde ürünlerimiz, kimyasal, metalurjik, fotovoltaik, nükleer enerji, lityum pil, elektronik yarı iletken, gıda, ilaç, otomobil, endüstriyel su arıtma ve diğer endüstrilerde asit ve alkali sıvıların, ultra saf suyun, içme suyunun, elektronik sınıfı saf suyun ve endüstriyel atık suyun boru hattı taşımacılığında yaygın olarak kullanılmıştır. Şu anda ZHEYI Grubu ülke genelinde 30 dan fazla satış şirketi kurmuş olup, her türlü ürün Avrupa, Amerika, Güneydoğu Asya ve diğer ülke ve bölgelere ihraç edilmekte olup, yurtiçi ve yurtdışı müşteriler tarafından yoğun ilgi görmektedir.

Genel bakış CPVC flanşlı küresel vana Uygulamalar ve Kurulum Gereksinimleri CPVC flanşlı küresel vana aşındırıcı sıvılar, yüksek saflıkta sıvılar ve sıcaklığa duyarlı ortamları işleyen endüstriyel bo...

daha fazla bilgi edin +86-15258772971

+86-15258772971

dinys009@163.com

dinys009@163.com