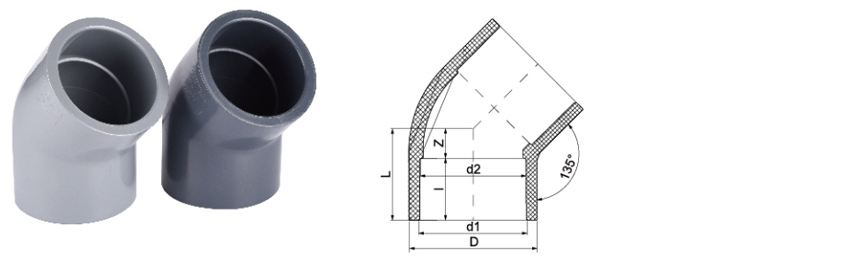

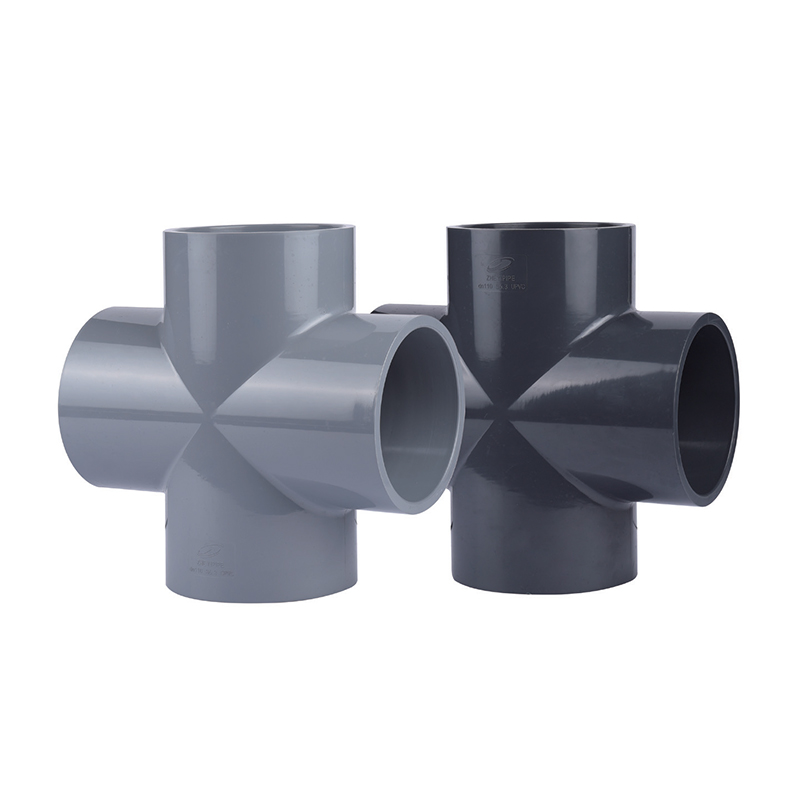

Performance comparison of UPVC and CPVC 45° elbows: corrosion resistance, temperature range and applicable scenario analysis

In industrial piping systems, UPVC (unplasticized polyvinyl chloride) and CPVC (chlorinated polyvinyl chloride) are two widely used thermoplastic materials, and their 45° elbows play a key role in fluid transportation. This article will compare the performance of the two in terms of corrosion resistance, temperature range and applicable scenarios, and analyze them in combination with the application needs of different industries.

1. Corrosion resistance comparison

UPVC: It has excellent resistance to acids, alkalis, salts and some organic solvents, but has weak tolerance to strong oxidizing acids (such as concentrated sulfuric acid and nitric acid) and aromatic hydrocarbons and chlorinated hydrocarbons, and is suitable for general corrosive environments.

CPVC: Further chlorination on the basis of UPVC, it has stronger chemical corrosion resistance, can withstand higher concentrations of strong acids, strong alkalis and some organic solvents, and is suitable for highly corrosive medium transportation.

Industry application analysis

Safe drinking water (Drinking Water): UPVC is suitable for cold water transportation, while CPVC can be used in hot and cold water systems, especially for occasions requiring high-temperature disinfection.

Metallurgy: CPVC is more suitable for strong corrosive processes such as pickling and electroplating, while UPVC can only be used in weak acid environments.

Photovoltaic: CPVC is suitable for high-concentration etching solution transportation, while UPVC can be used for general chemical pipelines.

Nuclear Power: CPVC has better high temperature and radiation resistance and is suitable for cooling water systems, while UPVC is only suitable for low-temperature water circulation.

Electronic Semiconductor: CPVC is more suitable for high-purity chemicals (such as etching solution, ultrapure water) transportation, while UPVC can be used for low-corrosive media.

Medicine: CPVC is suitable for high-temperature sterilization pipelines and corrosion-resistant liquid transportation, while UPVC has lower applicability.

Industrial Water Treatment: UPVC can be used in general filtration systems, while CPVC is suitable for high-temperature softened water or chemical agent addition.

Industrial Wastewater: CPVC is more suitable for strong acid/strong alkali wastewater treatment, while UPVC is only suitable for ordinary wastewater.

2. Temperature range comparison

UPVC: The working temperature range is usually 0°C ~ 60°C. Long-term high temperature can easily cause deformation and is only suitable for low-temperature or normal-temperature fluids.

CPVC: Stronger temperature resistance, working temperature range -40°C ~ 93°C, can withstand 110°C in a short period of time, suitable for high-temperature hot water, steam and thermal engineering material transportation.

Industry application analysis

Safe drinking water: UPVC is suitable for cold water pipes, and CPVC can be used for hot water supply systems.

Nuclear power plant: CPVC is suitable for medium and high temperature cooling media, and UPVC is limited to low-temperature circulating water.

Pharmaceutical industry: CPVC can be used for high-temperature sterilization pipes, while UPVC is not applicable.

Industrial water treatment: UPVC is suitable for normal temperature filtration, and CPVC can be used for boiler water supply or high-temperature softened water systems.

3. Summary of applicable scenarios

Recommended applications of UPVC 45° elbows

Low-temperature, low-corrosive environments, such as:

Municipal drinking water (cold water pipelines)

General chemical transportation in the photovoltaic industry

Low-temperature filtration systems for industrial water treatment

Recommended applications of CPVC 45° elbows

High-temperature, highly corrosive environments, such as:

High-purity chemicals and etching liquid transportation for electronic semiconductors

Pickling and electroplating liquid pipelines in the metallurgical industry

Medium- and high-temperature cooling systems in nuclear power plants

High-temperature sterilization and corrosion-resistant liquid transportation in the pharmaceutical industry

Strong acid/alkali wastewater systems in industrial wastewater treatment

+86-15258772971

+86-15258772971

dinys009@163.com

dinys009@163.com